Fabrication Services.

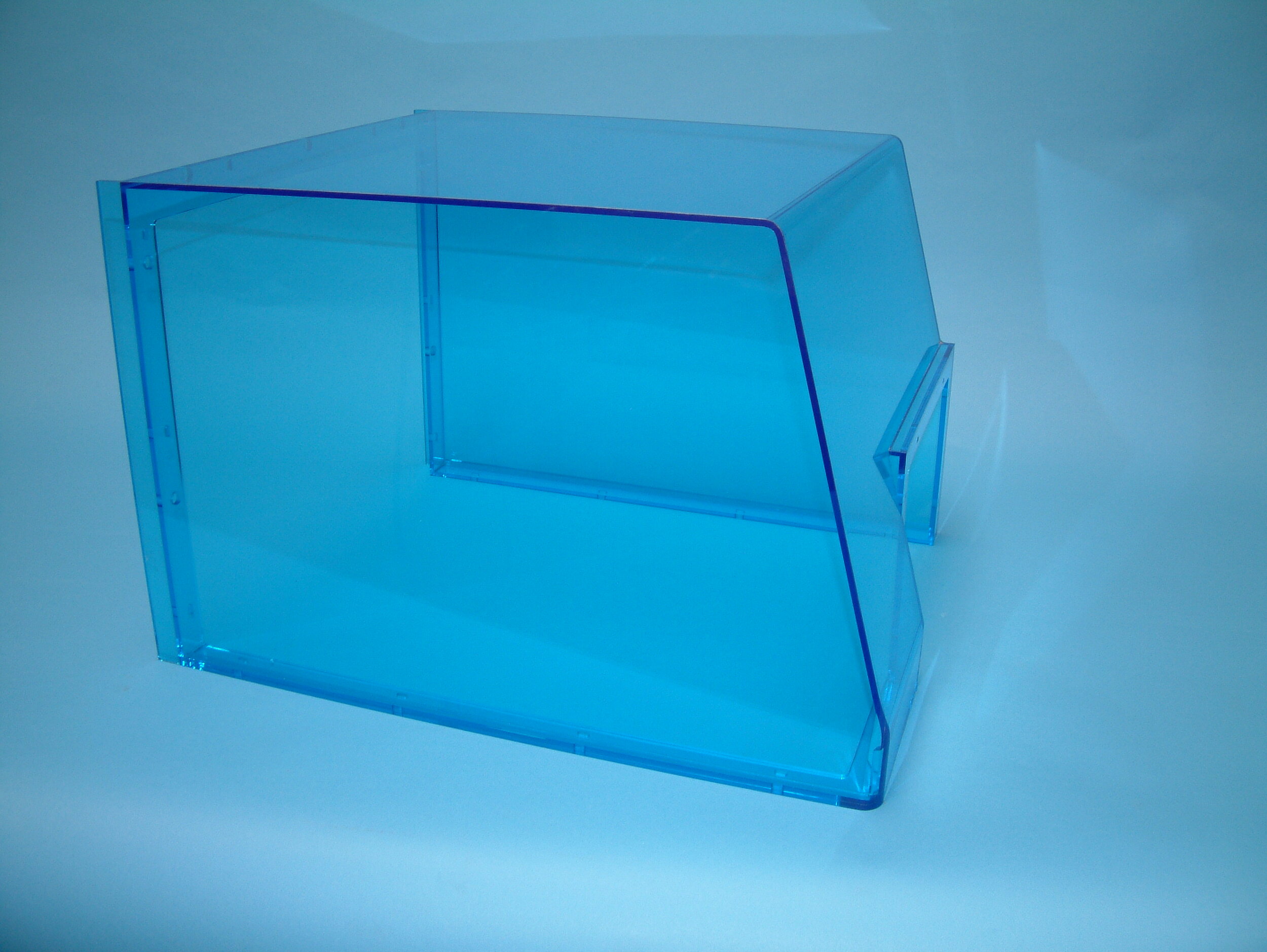

At ATI Plastics, we consider fabrication an art form. Our diverse blend of experience and capabilities is expressed through products that range from high-tolerance equipment that assists in the drug discovery process, to expertly crafted custom aquariums that bring another world into view. Our quality parts are carefully made in conformance with your industry demands and to the aesthetics that your customers expect.

Fabrication and Machining Techniques.

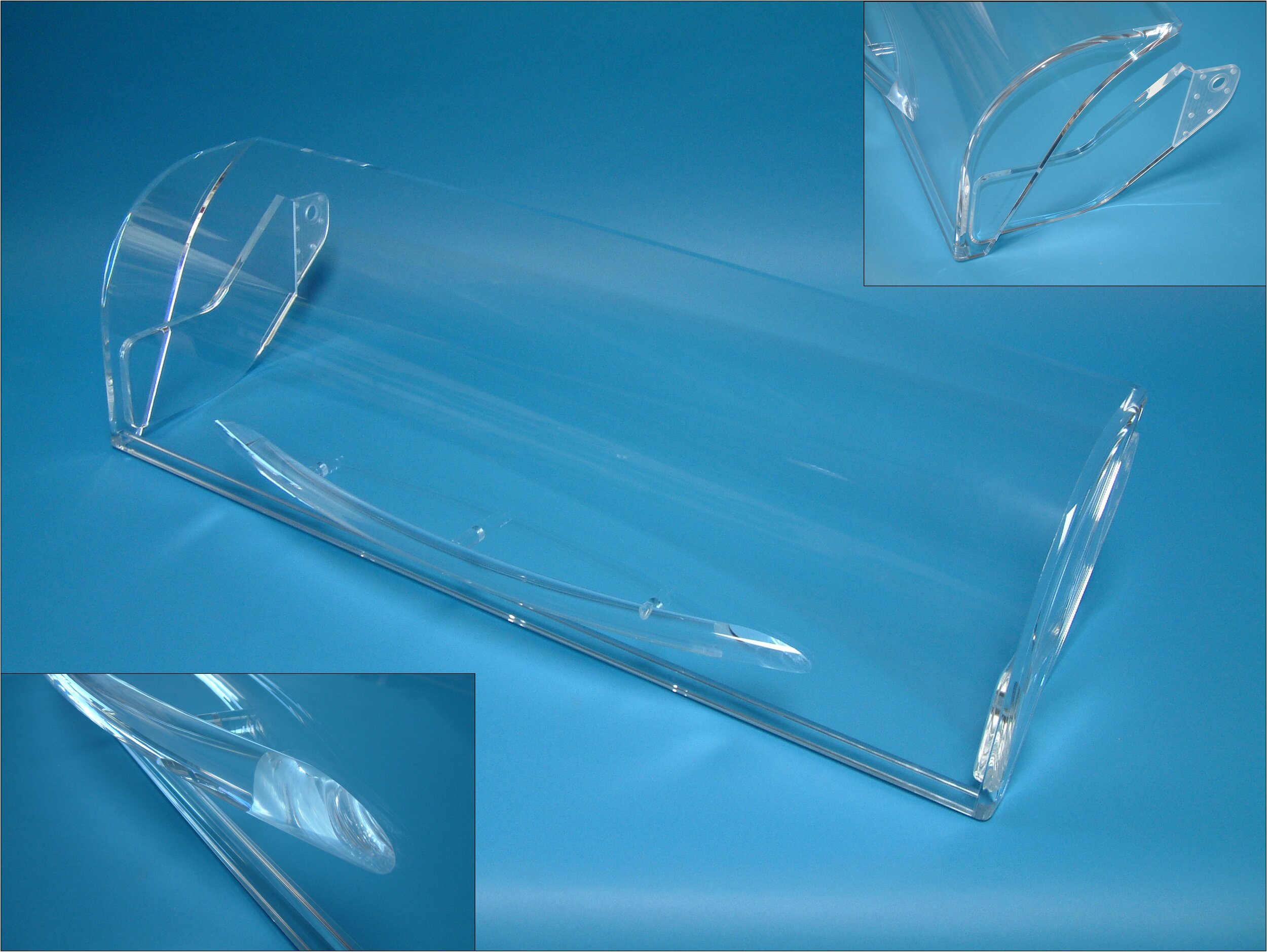

Vacuum, Pressure & Drape Forming Are all thermoforming processes. Vacuum Forming and Pressure forming are when a sheet of plastic material is heated to pliability, then pressed against a 3D mold by vacuuming out the air between the sheet and the mold. Pressure forming is the additional use of air pressure to create more defined detail on the formed part. Both of these process are automated. Drape forming involves heating plastic material and draping the heated material over or inside of a simple tool to create a curved surface such as a window or shield.

CNC Routing. Using our 3 & 5 axis Motionmaster CNC routers, we produce components used in production assembly or trim previously formed parts we manufactured. This automated process speeds up production and increases repeat-ability on production parts.

Machining. High precision cutting, drilling and taping of a variety of plastic materials is used to create components tat are used in various assemblies in the fabrication process.

Laminating. The assembly of formed, routed and machined components are put together typically by some form of lamination. Different solvents designed to bond like or dissimilar material are used primarily. Other adhesives, silicone, and specialized VHB(very high bond) tapes are sometimes necessary.

Cutting. Table saws are used to blank out material and cut to size parts used in the fabrication process

Drilling & Taping. Drill Presses are used in the fabrication to drill and sometimes tap holes in the production process when its better suited than using the CNC machines.

Polishing. One of the final processes of fabrication is polishing. Depending on the material and application, different types of polishing is preformed. These include Flame Polishing, Buff Polishing & Vapor Polishing.